No products in the cart.

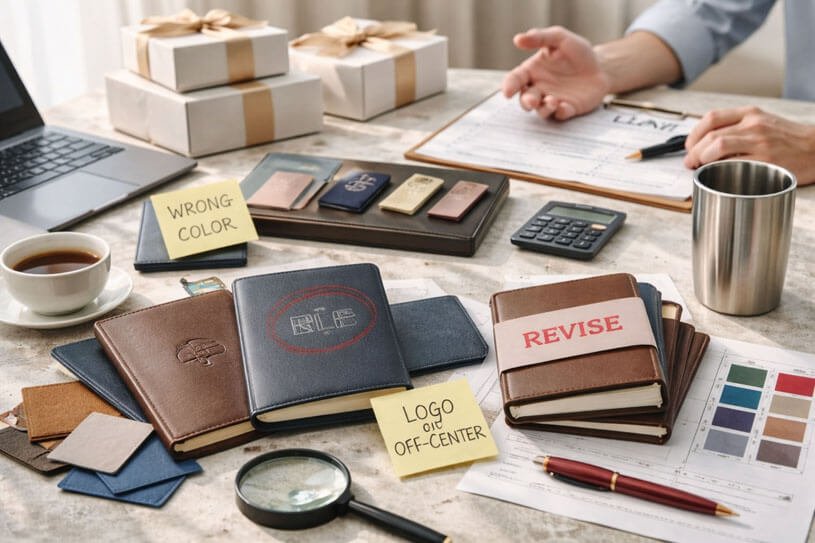

Corporate Gift Production Mistakes are rarely dramatic at the beginning. Most Corporate Gift Production Mistakes start quietly—during emails, internal approvals, and rushed decisions that feel harmless at the time. A logo looks “good enough,” a sample gets skipped to save a week, or a supplier says “no problem” without asking follow-up questions. In modern business culture, where speed is praised and timelines keep shrinking, these early missteps are incredibly common. But once manufacturing begins, Corporate Gift Production Mistakes stop being theoretical and start showing up as delays, cost increases, and uncomfortable internal conversations.

This article is written from a buyer’s perspective—for marketing teams, procurement managers, and brand leaders who want their custom gift projects to run smoothly. Not perfectly. Just without the avoidable mistakes that derail production before it even starts.

Why Corporate Gift Production Mistakes Are So Common Today

Ten years ago, corporate gifting projects moved slower. Approval chains were simpler. Expectations were lower. Today, everything has changed.

Modern corporate gifting sits at the intersection of branding, experience, and logistics. Buyers are expected to deliver premium results fast, often across borders, with more customization and fewer buffers. That pressure alone explains why Corporate Gift Production Mistakes happen more frequently than most teams expect.

Here’s what’s different now:

- Compressed timelines tied to events, launches, and campaigns

- More stakeholders involved in design and approval

- International sourcing as the default, not the exception

- Higher brand standards even for promotional items

None of these are bad things. But they raise the stakes. And when stakes go up, small errors matter more.

Corporate Gift Production Mistakes Buyers Make Before Manufacturing

This is where most projects quietly go off track. Not during shipping. Not during customs. But before production even begins.

Pre-Production Approval Mistakes That Look Minor (But Aren’t)

One of the most common Corporate Gift Production Mistakes is confusing visual approval with production approval.

Buyers often approve:

- A mockup instead of a production-ready proof

- A digital render instead of a physical sample

- A concept without final materials confirmed

Real example:

A buyer approves a notebook design based on a clean PDF mockup. The factory produces it correctly—but the leather texture feels cheaper than expected. No mistake in execution. Just a missed step in approval.

Pre-production approval mistakes happen because everyone wants to move fast. But manufacturing doesn’t work on intention. It works on exact specifications.

Custom Corporate Gift Mistakes in Design and Specifications

Custom corporate gift mistakes often start with design teams doing what they do best: pushing creativity. The problem is that not every design translates well into mass production.

Common issues include:

- Logos with gradients that don’t print cleanly

- Fonts too thin for embossing or debossing

- Artwork created without understanding production tolerances

These corporate gift design errors usually aren’t caught internally. They show up when samples arrive—or worse, when mass production has already started.

Smart buyers now involve suppliers earlier in the design phase, not later. It’s not about limiting creativity. It’s about making sure creativity survives manufacturing.

Branding Mistakes in Corporate Gifts That Hurt More Than You Think

Branding mistakes in corporate gifts don’t always scream “error.” Sometimes they whisper.

Slight color differences. Logo placement inconsistencies. Finishes that technically meet specs but feel off-brand when placed side by side.

Example:

A global brand orders gifts for three regional events. Same logo, same product, same supplier—but approvals are handled separately. The result? Three slightly different logo shades. Individually fine. Collectively messy.

These corporate gifting errors don’t break projects, but they weaken brand impact. And in a market where gifting is about experience, that matters.

Supplier Miscommunication: The Silent Killer of Gift Projects

If there’s one root cause behind most Corporate Gift Production Mistakes, it’s supplier miscommunication.

This doesn’t mean bad suppliers. It usually means:

- Assumptions instead of documentation

- Vague language like “premium,” “standard,” or “high-end”

- No clear owner for final decisions International sourcing adds another layer. Time zones slow feedback. Language differences soften warnings. A supplier might say “okay” when they actually mean “possible with risk.”

Buyers who reduce supplier miscommunication tend to:

- Ask for written confirmations

- Use checklists instead of casual emails

- Encourage suppliers to flag concerns early

The best suppliers don’t just follow instructions. They question them.

International Sourcing Risks Buyers Often Underestimate

International sourcing has unlocked incredible flexibility and cost advantages. But it also introduces risks that newer buyers often overlook.

Common international sourcing-related Corporate Gift Production Mistakes include:

- Forgetting regional holidays and shutdowns

- Underestimating shipping buffers

- Assuming compliance standards are universal

Real-world scenario:

A U.S.-based marketing team schedules production around a product launch—without realizing the factory observes a week-long regional holiday. Production pauses. Timelines slide. Nobody did anything “wrong,” but the mistake still costs time.

Experienced buyers build buffers. Inexperienced ones build apologies.

How Corporate Gift Production Mistakes Turn Into Delays and Cost Increases

One small mistake rarely stays small.

A missed approval leads to a revised sample.

A revised sample pushes production.

Production pressure leads to rush fees.

Rush production increases error risk.

This is how corporate gift production delays happen—not because suppliers are slow, but because early decisions weren’t fully locked.

Custom gift manufacturing issues tend to compound. That’s why buyers who plan carefully before mass production usually move faster overall.

Corporate Gift Production Mistakes in Fast-Moving Business Culture

Contemporary business culture rewards speed, flexibility, and responsiveness. But manufacturing rewards clarity and commitment.

This mismatch creates tension.

Buyers are praised for moving quickly.

Factories are punished for moving inaccurately.

Corporate Gift Production Mistakes often sit right in that gap.

More buyers are now adjusting how they work:

- Slower approvals, faster execution

- Fewer last-minute changes

- Earlier supplier involvement

It’s a shift from “get it done fast” to “get it right once.”

Mistakes Before Mass Production Buyers Regret Most

When buyers look back on projects that went wrong, the regrets are surprisingly consistent:

- “We should’ve approved the physical sample.”

- “We changed the logo too late.”

- “We assumed the supplier understood.”

- “We didn’t confirm materials early enough.”

These mistakes before mass production are painful because they feel avoidable in hindsight. And they usually are.

How Experienced Buyers Reduce Corporate Gift Production Mistakes

Seasoned buyers don’t avoid mistakes by being smarter. They avoid them by using systems.

They:

- Lock specs before pricing

- Separate creative approval from production approval

- Work with suppliers who flag risks early

Some buyers now actively look for partners who operate with a zero-error mindset—not perfection, but prevention. Suppliers who would rather slow a project down by a day than let it fail quietly later.

That mindset is becoming more valuable as customization increases and timelines tighten.

A Practical Buyer Checklist to Avoid Corporate Gift Production Mistakes

Before you approve mass production, ask yourself:

- Is the artwork production-ready—not just visually approved?

- Have materials, finishes, and colors been physically confirmed?

- Are branding guidelines shared and acknowledged?

- Have international timelines been stress-tested?

- Is there one clear decision owner?

This checklist won’t eliminate all Corporate Gift Production Mistakes, but it will eliminate most of the expensive ones.

Why Supplier Choice Matters More Than Ever

In today’s environment, suppliers aren’t just vendors. They’re risk managers.

The difference between a smooth project and a painful one often comes down to whether your supplier:

- Challenges unclear instructions

- Communicates proactively

- Flags potential problems early

Some buyers choose partners like Giftdonna not because they promise speed, but because they focus on getting things right before production starts. That quiet diligence doesn’t show up in marketing—but it shows up in results.

Final Thoughts: Avoiding the Mistakes That Matter Most

Corporate Gift Production Mistakes don’t usually come from bad intentions or poor planning. They come from pressure, speed, and assumptions that feel reasonable in the moment. As corporate gifting becomes more customized, more global, and more brand-sensitive, buyers who slow down early tend to win later. By working with suppliers who prioritize clarity and prevention, you reduce risk before manufacturing even begins—and protect the success of the entire project from day one. If you’re planning your next custom order, avoiding Corporate Gift Production Mistakes may be the most valuable decision you make.

Call to Action

If you’re preparing a custom corporate gift project and want a second set of experienced eyes before production starts, Giftdonna is always happy to review specifications, timelines, and potential risk points—no pressure, no sales pitch. Sometimes catching one small issue early is all it takes to keep everything else on track.

Corporate Gift Production Mistakes FAQ

What are Corporate Gift Production Mistakes?

Corporate Gift Production Mistakes are errors buyers make before manufacturing begins, such as unclear specifications, rushed approvals, design mismatches, or supplier miscommunication. These mistakes often lead to delays, rework, and higher costs once production starts.

Why do Corporate Gift Production Mistakes usually happen before manufacturing?

Most Corporate Gift Production Mistakes happen early because buyers are focused on speed rather than production readiness. Common causes include:

- approving designs without production confirmation

- skipping physical samples

- incomplete branding guidelines

- assumptions about materials or timelines

Once manufacturing begins, fixing these issues becomes much harder.

What are the most common pre-production approval mistakes?

Typical pre-production approval mistakes include:

- approving digital mockups instead of physical samples

- confirming visuals but not materials or finishes

- overlooking size tolerances and logo placement rules

These mistakes seem small but often create major custom gift manufacturing issues later.

How do corporate gift design errors affect production?

Corporate gift design errors can cause problems such as:

- logos that don’t emboss or print cleanly

- colors that shift on different materials

- designs that exceed manufacturing limits

What works on screen does not always work in mass production.

How does supplier miscommunication cause Corporate Gift Production Mistakes?

Supplier miscommunication happens when expectations are not clearly documented. This is especially common with international sourcing and may include:

- vague terms like “premium” or “standard”

- missing technical details

- delayed feedback due to time zones

Clear communication early helps prevent costly mistakes later.

Are international suppliers a higher risk for corporate gift production?

International suppliers are not automatically risky, but international sourcing adds complexity. Buyers must account for:

- shipping timelines

- regional holidays

- compliance standards

- production buffers

Ignoring these factors often leads to corporate gift production delays.

What mistakes before mass production are hardest to fix?

The hardest mistakes before mass production include:

- approving the wrong sample

- changing branding after production starts

- discovering material issues too late

- underestimating lead times

These issues usually result in added costs or compromised quality.

How can buyers reduce Corporate Gift Production Mistakes?

Buyers can reduce Corporate Gift Production Mistakes by:

- confirming production-ready artwork

- approving physical samples whenever possible

- locking specifications before pricing

- working with suppliers who flag risks early

Preparation is one of the most effective risk-control tools.

Why does supplier experience matter so much?

Experienced suppliers help buyers avoid Corporate Gift Production Mistakes by identifying potential issues before manufacturing begins. They focus on prevention rather than explanation after problems occur.

Can Giftdonna help prevent Corporate Gift Production Mistakes?

Giftdonna helps buyers reduce Corporate Gift Production Mistakes by reviewing specifications, timelines, and customization details before production. The goal is to catch risks early and keep projects moving smoothly without last-minute surprises.